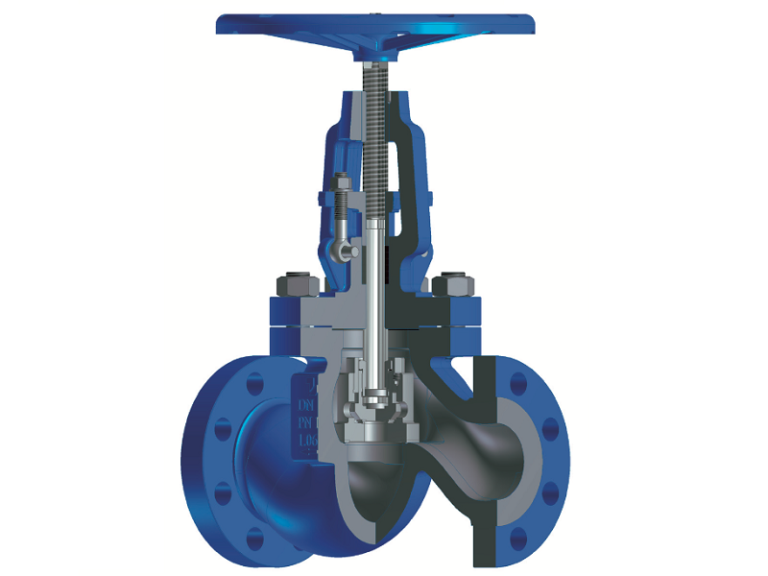

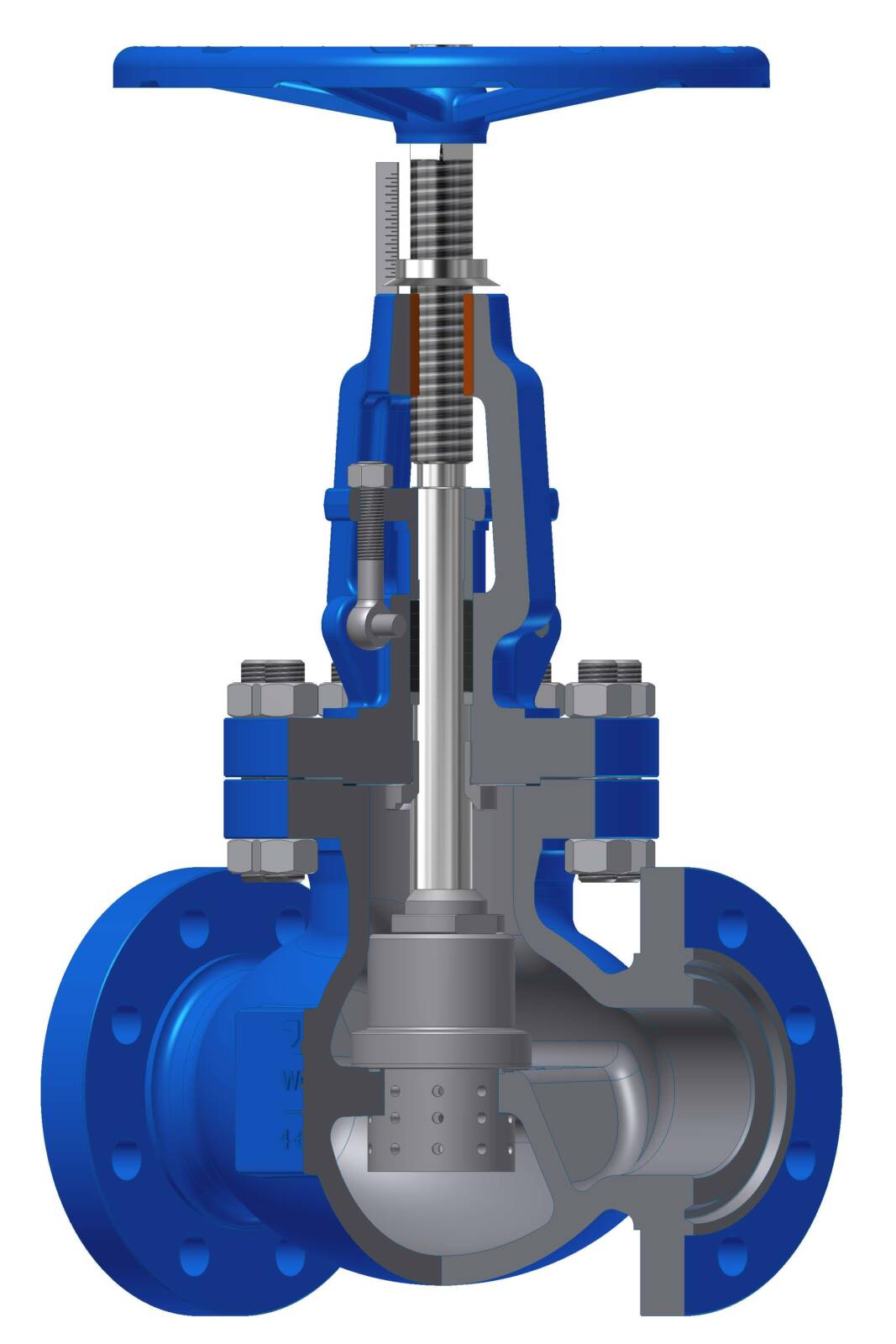

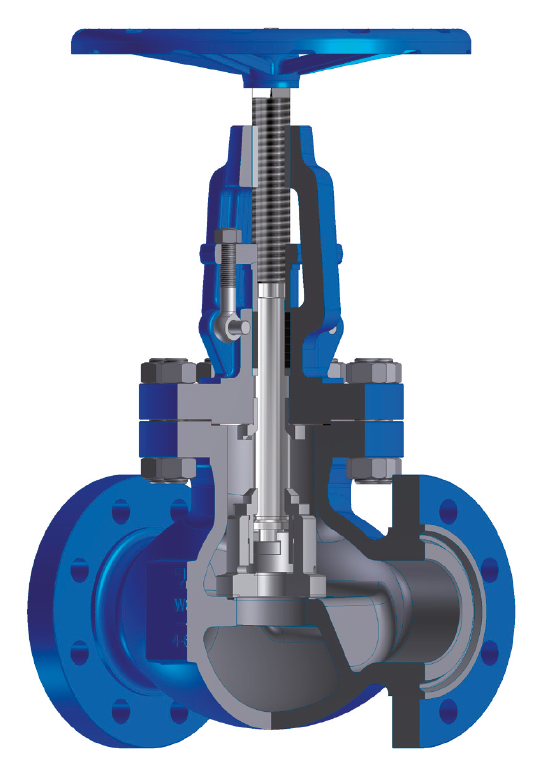

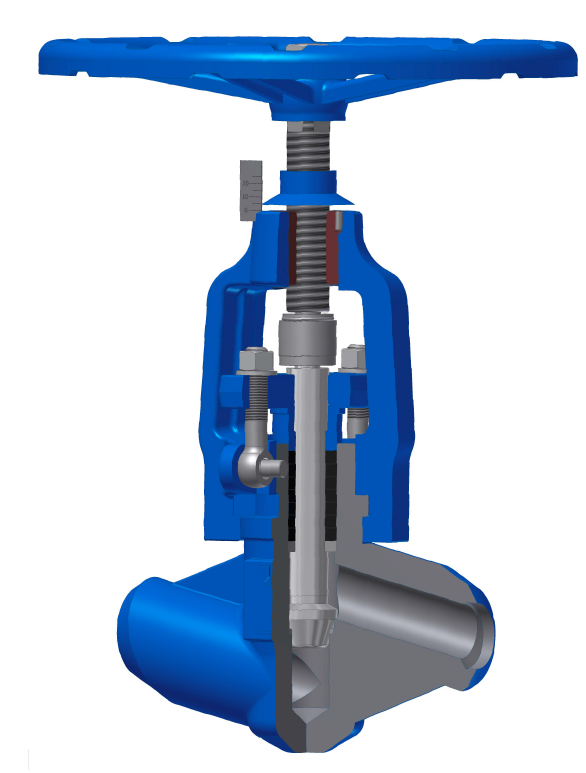

Globe Stop and Check Valves [VENSC]

EN 13709

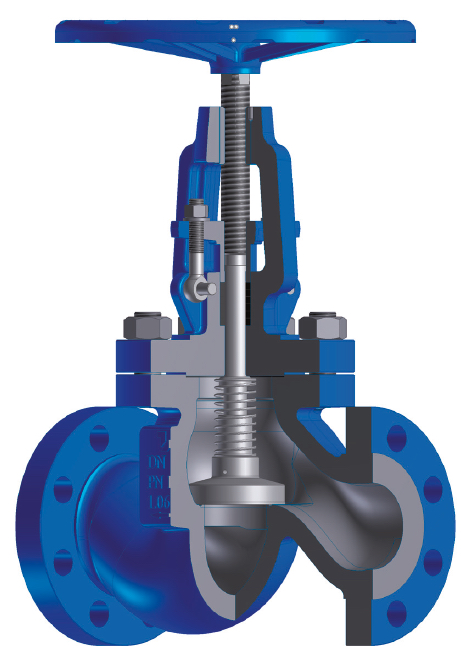

Description

DN 15 ÷ DN 150

PN 16 ÷ PN 160

Execution

- Forged or casted body and bonnet

- Bolted bonnet (BB)

- Rising stem (RS), outside screw and yoke (OS&Y)

- Built-in spring converts globe stop valve into check valve

- Seats are integral or welded on

Applications:

- Power plant, Chemical, Petrochemical, Refining

Media:

- Depending on the valve materials: water, steam, gas, oil and oil derivates and other non aggressive media

Pressure and temperature

- Pressure up to160 bar

- Temperature up to 600oC

Materials

- Carbon, heat resistant alloy and stainless steels

Advantages

- Long service life

- Respect to emission standards

- Easy handling and maintenance

- Stem packing replacement in working conditions

Options

- Electric, hydraulic or pneumatic actuator

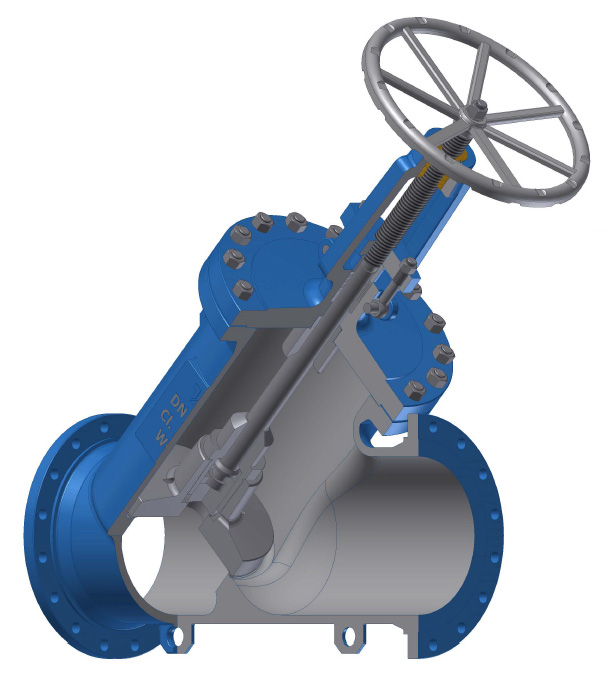

- Y-Type (VENSCY)

- Angle Type (VENSCA)

- Position indicator

- Extended stem

- Locking device

- Seats and sealing made of elastic materials

- Flanges and welding ends according to : GOST, DIN, ASME, etc.

- Other paint finishes are available upon customer’s request

- Valve complete with counter flanges, bolt-ing and gaskets

Testing: Every produced valve was tested accord-ing to EN 12266