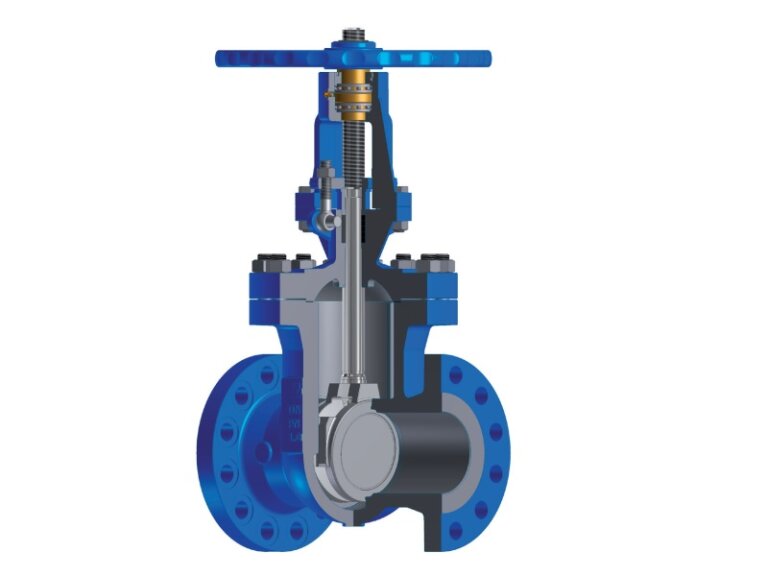

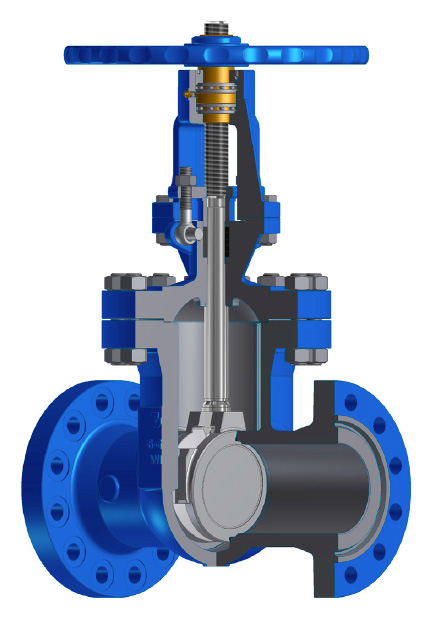

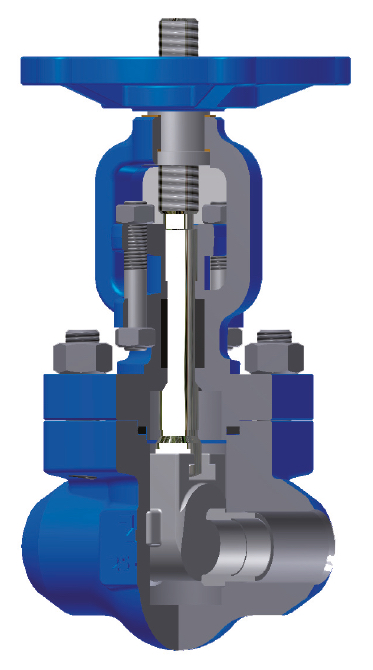

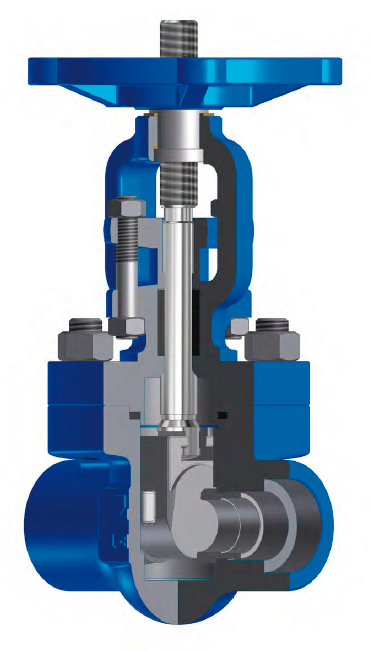

High Pressure Gate Valves [GHP]

API 598 or EN 12266

Description

NPS 1/2”(DN 15) ÷ NPS 16” (DN 400)

Class 600 ÷ Class 2500

PN 100 ÷ PN 400

Design

- Closed-Die-Forged, welded construction or cast body

- Pressure seal design

- Rising stem (RS), outside screw and yoke (OS&Y)

- Split wedge type obturator • Hard faced seats

Applications

- Power plant, Chemical, Petrochemical, Refining, water supply and other

Media: Depending on the gate valves materials for: water, steam, gas, oil and other non-aggressive media

Pressure and temperature

- Class 600 ÷ Class 2500

- Pressures up to 400 bar

- Temperatures up to 600 oC

- p/t according to EN 12156-1 and ASME B16.34 (Appendix A)

Materials

- Carbon and heat resistant alloys

Advantages

- Long service life

- Respect to emission standards

- Easy handling and maintenance

Options

- Electric actutor

- Pneumatic actuator

- Hydraulic actuator

- Position indicator

- Limit switches

- Locking device

- Chain-wheel

- Spring loaded stuffing box (SLSB)

- With by-pass Valve

- With equalizing pipe and by-pass valves

- With equalizing pipe to the 3rd chamber

- With hole in the wedge

- With hole in the seat

- With conection for safety valve

- Flanges and welding ends according to: DIN, EN, GOST, etc.

- Other paint finishes are available upon customer’s request

Testing

Every produced valve is tested according to API 598 or EN 12266