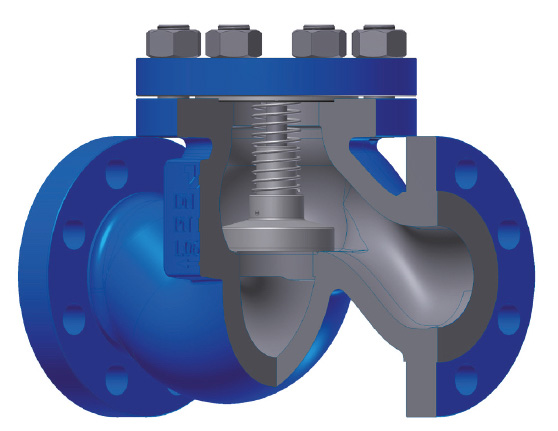

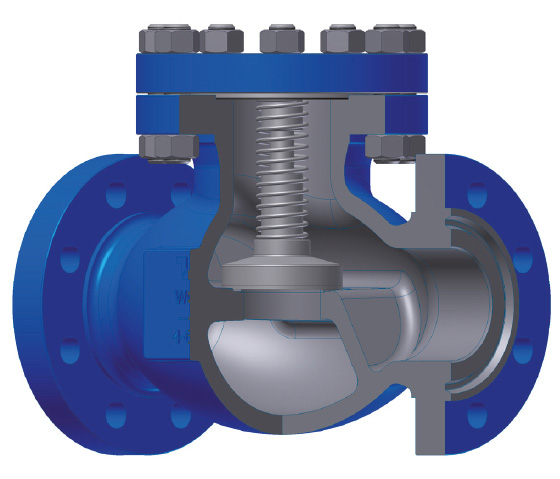

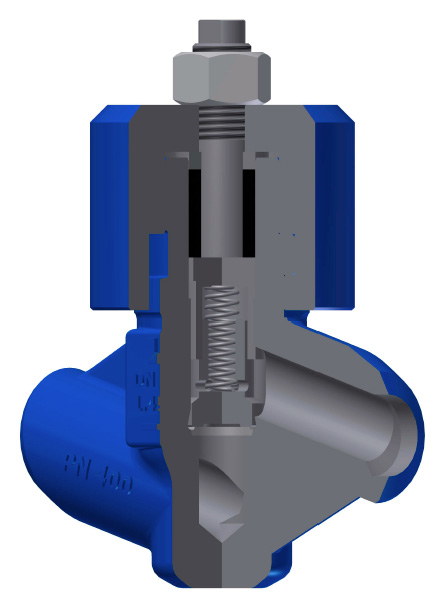

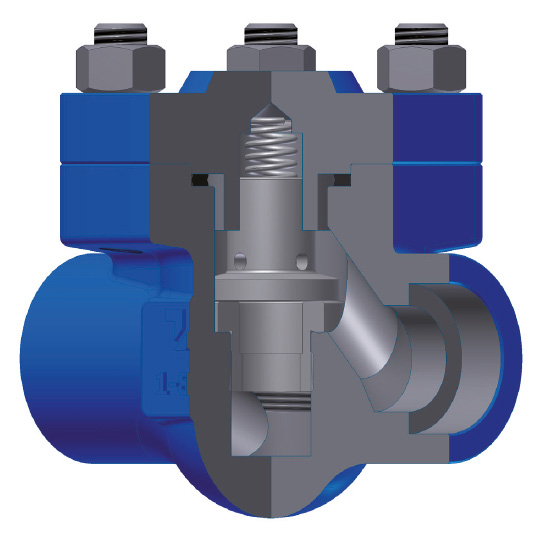

Forged Lift Check Valves [CAPL]

API 602

Description

DN 8 ( 1/4”) ÷ DN 50 ( 2”)

Class 150 ÷ Class 1500

Design

- Forged body and cover

- Bolted cover (BC)

- Guided disc pressed with spring on the body seat (Lift type)

- Body seats are integral or welded on

Applications

- Refining, Petrochemical, Chemical, Power plant

Media

Depending on the valve materials: water, steam, gas, oil and oil derivates and other non aggressive media

Pressure and temperature

- Class 150 ÷ Class 1500

- Temperature up to 600 oC

Materials

- Carbon, heat resistant alloy and stainless steels

Advantages

- Possibility of installation in any position

- Long service life

- Respect to emission standards

- Easy handling and maintenance

Options

- Seating surfaces made of special alloys or elastic materials

- Flanges and welding ends according to : EN, DIN, GOST, etc.

- Other paint finishes are available upon customer’s request Valve complete with counter flanges, bolting and gaskets

Testing

- Every produced valve was tested according to API 598