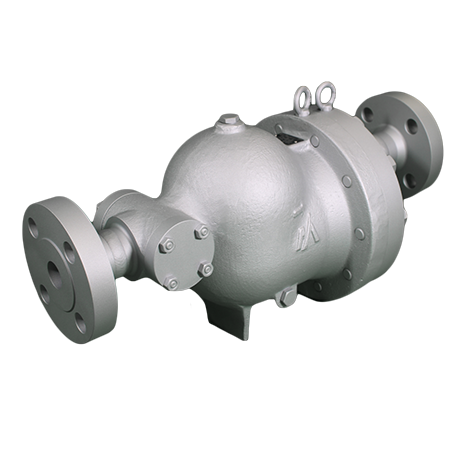

Condensate drain GWH70 / NEW!

- Suitable for condensate recovery

- Horizontal installation

- Automatic venting

- Option

- Customized flange

- ASTM material available

Properties

-

Suitable for steam processes with medium capacity

Can move continuously to change the degree of opening of the valve according to the incoming condensate to ensure maximum heat exchange capacity.

-

High discharge capacity

A balanced valve with two connections enables a larger capacity with a smaller housing.

-

Easy maintenance

The inner strainer can be removed quickly and easily without having to remove the siphon from the pipe.

-

Protection against corrosion

Use of stainless steel components at the corrosion-prone outlet.

-

Condensate recovery

With its high back pressure tolerance, this model is suitable for condensate return.

-

Fast commissioning

Discharges cold air and cold condensate automatically.

Typical applications

- Suitable for high-pressure process systems

Welding socket

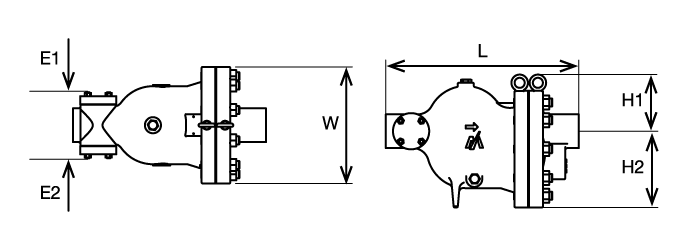

| Nominal width | Dimensions (mm) | Maintenance range (mm) | Weight | ||||

| L | H1 | H2 | W | E1 | E2 | kg | |

| 1½” | 480 | 140 | 190 | 290 | 110 | 110 | 62 |

| 2″ | |||||||

*Standards:ASME B16.34 Class900, JIS sch 160

Welding end

| Nominal width | Dimensions (mm) | Maintenance range (mm) | Weight | ||||

| L | H1 | H2 | W | E1 | E2 | kg | |

| 1½” | 480 | 140 | 190 | 290 | 110 | 110 | 62 |

| 2″ | |||||||

*Standards:ASME/JPI Class600, Class900, JIS 40K, 63K

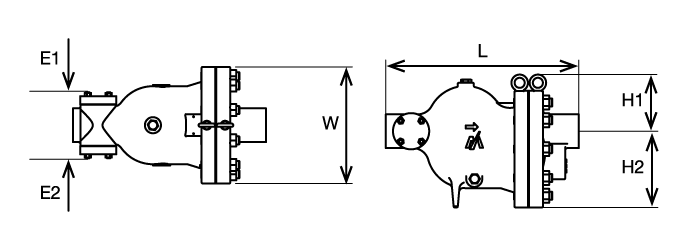

Flange

Flange standards ASME/JPI, JIS

| Nominal width | Dimensions (mm) | Maintenance range (mm) | Weight | ||||

| L | H1 | H2 | W | E1 | E2 | kg | |

| 1½” | 630 | 140 | 190 | 290 | 110 | 110 | 75 |

| 2″ | 85 | ||||||

*Standards:ASME/JPI Class600, Class900, JIS 40K, 63K

Flanged standard PN40, PN63

| Nominal width | Dimensions (mm) | Maintenance range (mm) | Weight | ||||

| L | H1 | H2 | W | E1 | E2 | kg | |

| 1½” | 630 | 140 | 190 | 290 | 110 | 110 | 72 |

| 2″ | |||||||

*Standards:PN40, PN63

Customized dimensions on request.

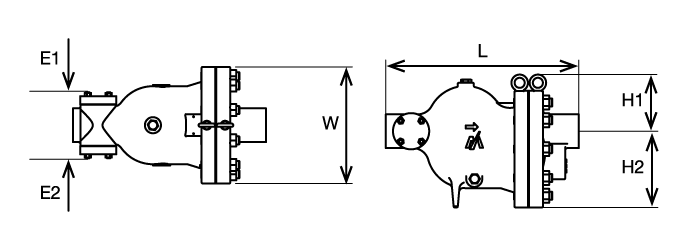

| Model | Connection | Max. operating pressure | Max. differential pressure | Max. Operating temperature |

Body Material |

|

| Type | Nominal diameter | (bar) | (bar) | (℃) | ||

| GWH70-W | Socket Weld* | 1½” | 65 at 425℃ |

65 | 425 at 65bar |

Cast steel A216 WCB |

| 2″ | ||||||

| GWH70-BW | Butt Weld* | 1½” | ||||

| 2″ | ||||||

| GWH70-F | Flanged* | 1½” | ||||

| 2″ | ||||||

*Available standards

Welding socket: ASME B16.34 Class900, JIS sch 160

Welding end: ASME B16.25 Sch160, JIS Sch 160

Flange: ASME/JPI Class600, Class900, JIS 40K, 63K, PN40, PN63

- Max. permissible pressure (PMA): 65 bar (psig)

- Max. permissible temperature (TMA): 425℃ at 65bar

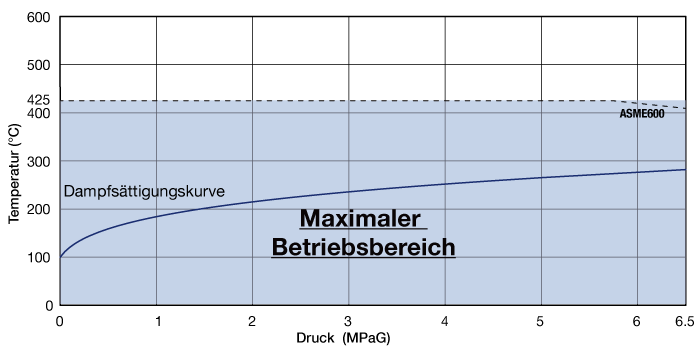

Max. Operating pressure and max. operating temperature

(conditions for the housing design: PN63)

- PMO: 65bar at 425 ℃

- TMO: 425℃ at 6.5bar

Thermal insulation (customized production)

ーFirst-class insulation performance and energy savingsー