Steam trap ER25

- SCCV system

- Suitable for condensate recovery

- Horizontal installation

- Option

- Customized flange

- ASTM material available

- Awarded in 1978 for outstanding energy savings

Properties

-

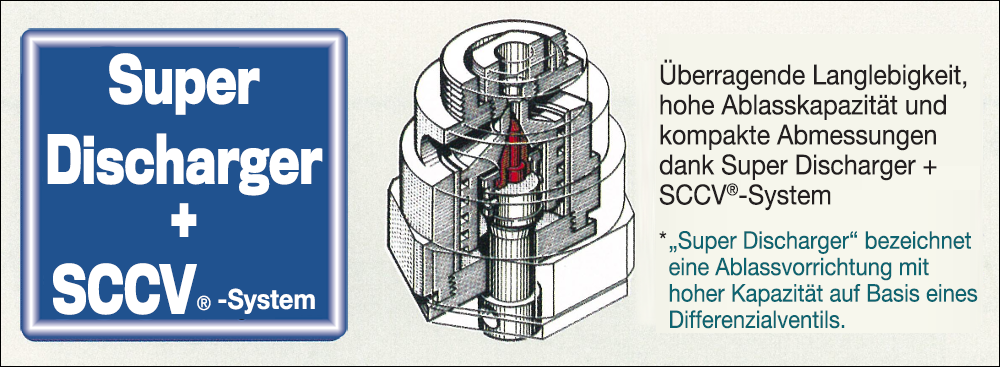

Outstanding durability

The SCCV system valve and the robust lever, as well as the internal components made of stainless steel, ensure outstanding durability of the steam trap.

-

Easy maintenance

This model can also be repaired built-in and is therefore quick and easy to maintain.

-

Condensate recovery

With its high back pressure tolerance, this model is suitable for condensate return at a pressure of up to 90 % of the inlet pressure.

-

Completely closed

The double steam separation mechanism (channel with U-profile and inverted bucket float) ensures reliable steam separation and guarantees the tightness of the steam trap.

-

No vapor or air entrapment

Thanks to a small ventilation opening in the upper part of the bell float, this model does not trap steam or air.

* SCCV system” is the abbreviation for “Self Closing and Centering Valve System”.

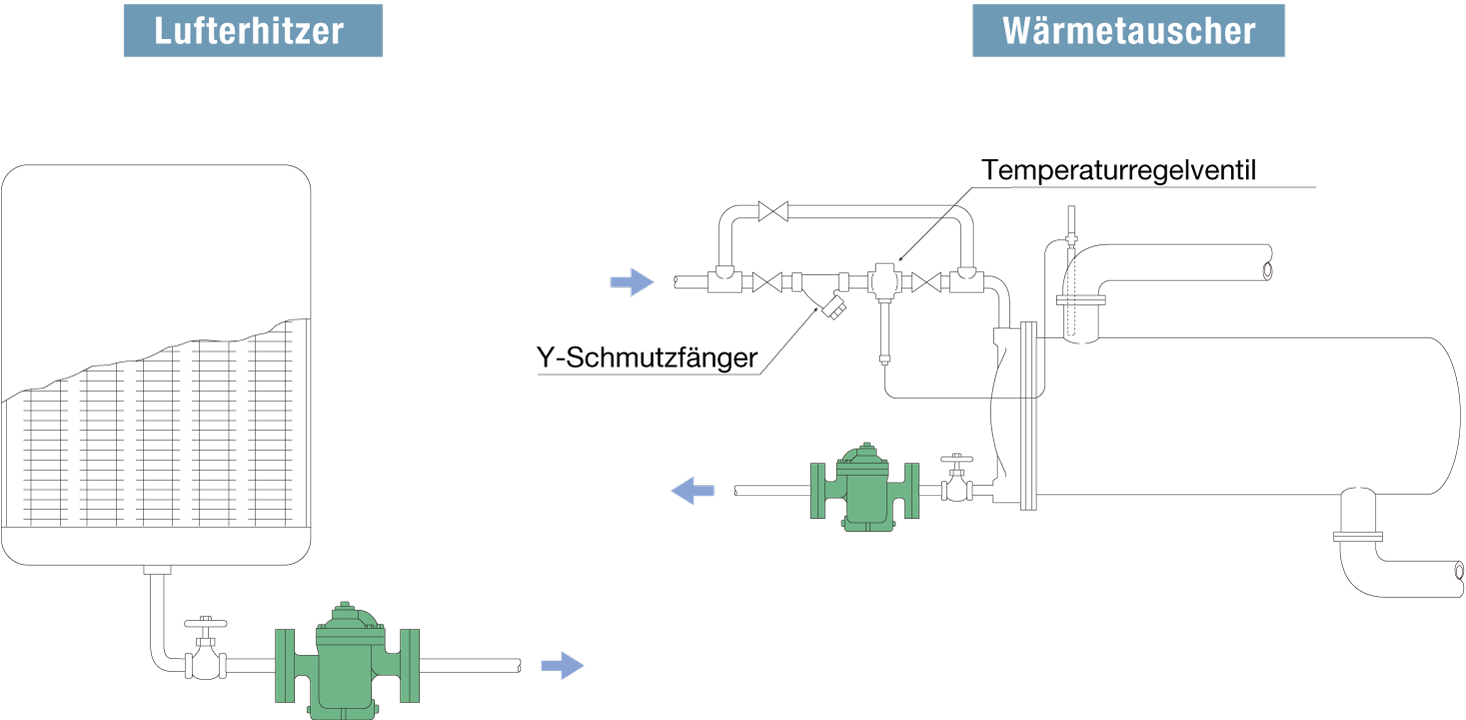

Typical applications

- Suitable for use in a wide range of sectors such as agriculture, food production, dyeing, cleaning and air conditioning.

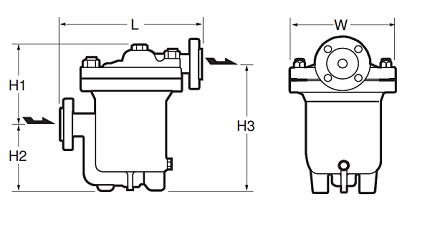

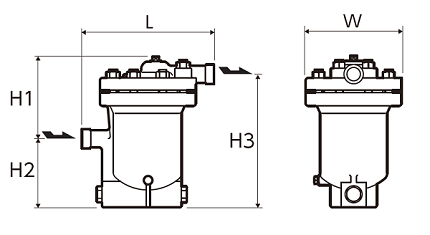

Flange

| Nominal width | Flange standards | Dimensions (mm) | Weight | ||||

| L | H1 | H2 | H3 | W | (kg) | ||

| 1/2″ 3/4″ 1″ |

JIS(RF) 10K,20K,30K,40K |

340 | 210 | 180 | 345 | 248 | 51,0 |

| ASME/JPI(RF) 150lb,300lb |

|||||||

| ASME/JPI(RF) 600lb |

345 | ||||||

| ASME/JPI(RJ) 150lb,300lb,600lb |

|||||||

| JIS(RF) 63K |

380 | 58,0 | |||||

| ASME/JPI(RF) 900lb |

|||||||

| ASME/JPI(RJ) 900lb,1500lb |

51,0 | ||||||

| 1 1/4″ 1 1/2″ 2″ |

JIS(RF) 10K,20K,30K,40K |

380 | 58,0 | ||||

| ASME/JPI(RF,RJ) 150lb,300lb,600lb |

|||||||

| JIS(RF) 63K |

400 | ||||||

| ASME/JPI(RF,RJ) 900lb |

|||||||

| ASME/JPI(RJ) 1500lb |

|||||||

| Nominal width | Flange standards | Dimensions (mm) | Weight | |||

| L | H1 | H2 | H3 | (kg) | ||

| DN15-25 | DIN PN40 | 340 | 210 | 180 | 345 | 51,0 |

| DIN PN63/PN100 (DN15/DN20) | 345 | |||||

| DIN PN63/PN100 (DN25) | 380 | |||||

| DN32-50 | DIN PN40/PN63/PN100 | 400 | 58,0 | |||

* Customized dimensions on request.

Welding socket

| Nominal width | Dimensions (mm) | Weight | ||||

| L | H1 | H2 | H3 | W | (kg) | |

| 1/2″ 3/4″ 1″ 1 1/4″ 1 1/2″ |

340 | 210 | 180 | 345 | 248 | 48,0 |

| 2″ | 380 | 49,0 | ||||

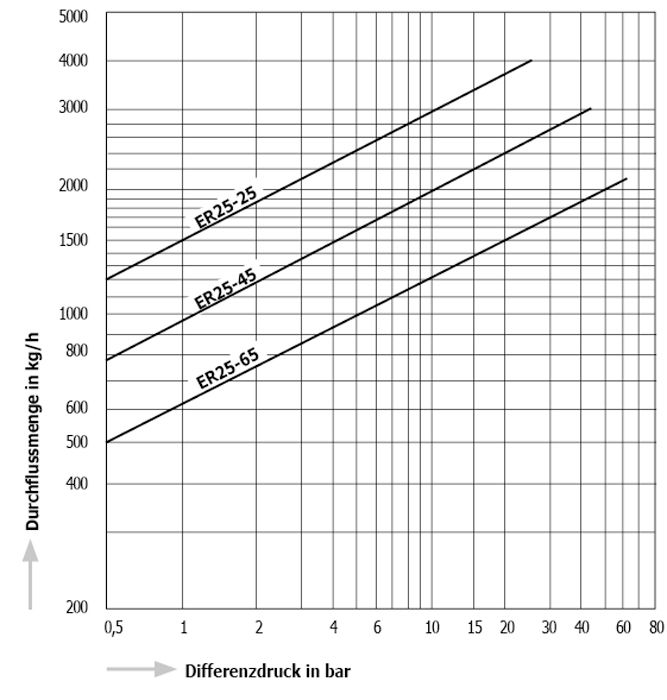

| Model | Connection | Max. operating pressure | Max. differential pressure | Max. Operating temperature | Housing material | |

| Type | Nominal diameter | (bar) | (bar) | (℃) | ||

| ER25-25 | Flange

RF,RJ |

1/2″ | 25 | 25 | 425 | Cast steel

SCPH2/WCB |

| 3/4″ | ||||||

| 1″ | ||||||

| 1 1/4″ | ||||||

| 1 1/2″ | ||||||

| 2″ | ||||||

| ER25-45 | 1/2″ | 44 | 44 | |||

| 3/4″ | ||||||

| 1″ | ||||||

| 1 1/4″ | ||||||

| 1 1/2″ | ||||||

| 2″ | ||||||

| ER25-65 | 1/2″ | 64 | 64 | |||

| 3/4″ | ||||||

| 1″ | ||||||

| 1 1/4″ | ||||||

| 1 1/2″ | ||||||

| 2″ | ||||||

| ER25W-25 | Welding socket

SW |

1/2″ | 25 | 25 | 425 | Cast steel

SCPH2/WCB |

| 3/4″ | ||||||

| 1″ | ||||||

| 1 1/4″ | ||||||

| 1 1/2″ | ||||||

| 2″ | ||||||

| ER25W-45 | 1/2″ | 44 | 44 | |||

| 3/4″ | ||||||

| 1″ | ||||||

| 1 1/4″ | ||||||

| 1 1/2″ | ||||||

| 2″ | ||||||

| ER25W-65 | 1/2″ | 64 | 64 | |||

| 3/4″ | ||||||

| 1″ | ||||||

| 1 1/4″ | ||||||

| 1 1/2″ | ||||||

| 2″ | ||||||

* Available flange standards: ASME/JPI, DIN, JIS

* Customized dimensions on request.