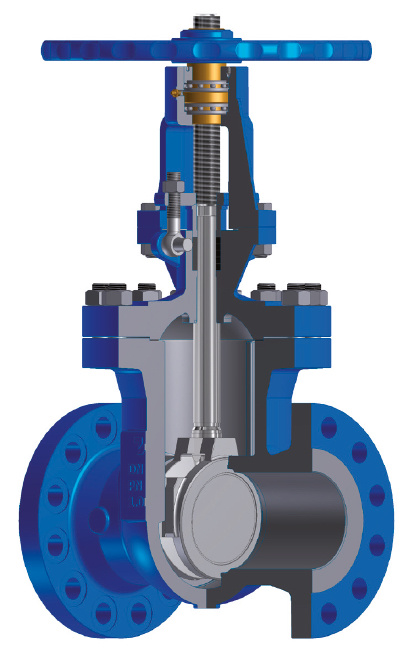

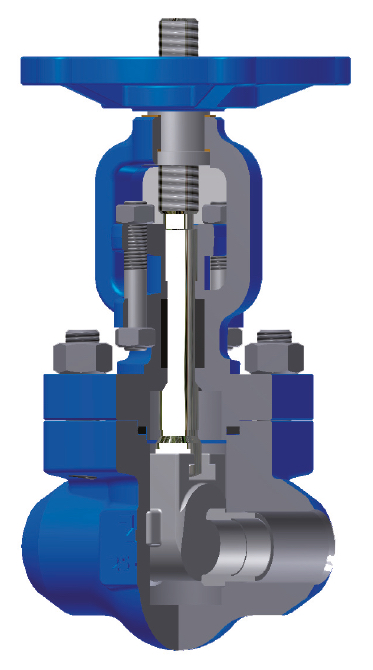

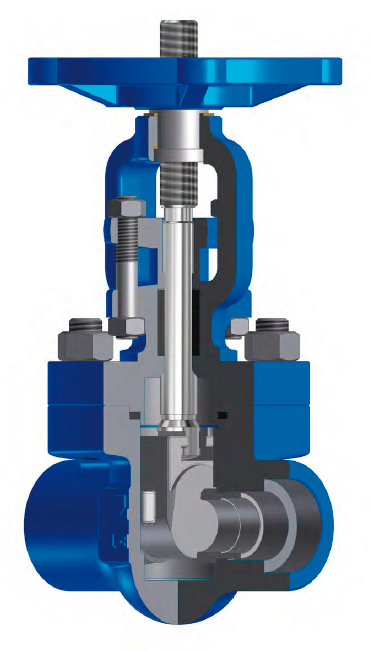

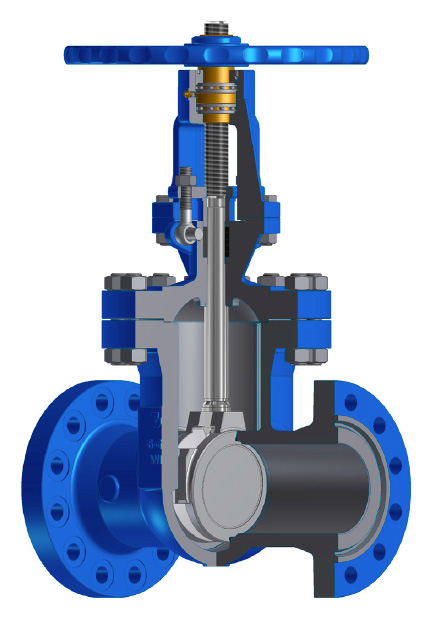

Gate valves [GAC]

API 600

Description

DN 50 (2”) ÷ DN 650 (26”)

Class 150 ÷ Class 1500

Design

- Casted body and bonnet

- Bolted bonnet (BB)

- Rising stem (RS), outside screw and yoke (OS&Y)

- Wedge may be one-piece flexible, solid or split wedge type

Applications

- Refining, Petrochemical, Chemical, Power plant

Media: Depending on the gate valve materials: Carbon, heat resistant alloys and stainless steels > Carbon steel, heat resistant alloys and stainless steels

Pressure and temperature

- Class 150 ÷ Class 1500

- Temperature up to 600°C

Materials

- Carbon, heat resistant alloys and stainless steels

Advantages

- Long service life

- Compliance with emission standards

- Easy handling and maintenance

- Replacing the stuffing box packing under operating conditions

Options

- Electric, hydraulic or pneumatic actuator

- Position indicator

- Extended stem

- Locking device

- Non rising stem and solid wedge

- Hole in the wedge (overpressure safety design)

- Spring loaded stuffing box (SLSB)

- With equalizing pipe

- With bypass Valve

- With equalizing pipe and bypass valves

- Flanges and welding ends according to: EN, DIN, GOST, etc.

- Other paint finishes are available upon customer’s request

- Gate valve complete with counter flanges, bolting and gaskets.

Testing

Every produced gate valve was tested according to API 598