Strainers [SBS]

BS / ANSI

Description

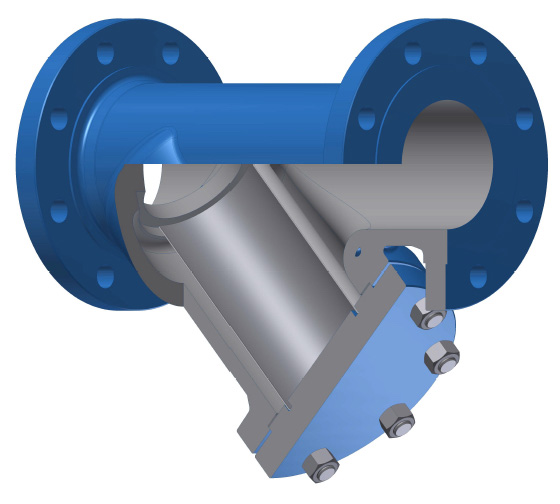

DN 50(2”) ÷ DN 350(14”)

Class 150 ÷ Class 900

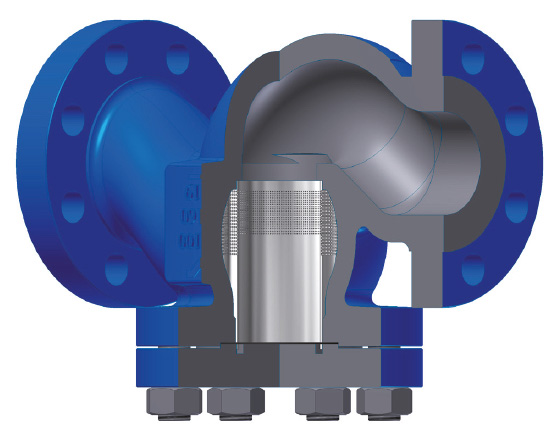

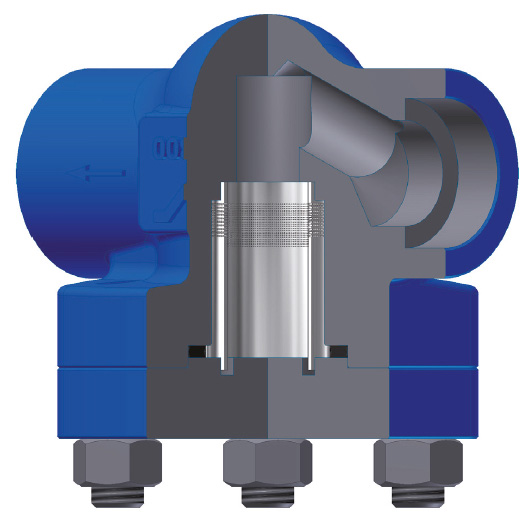

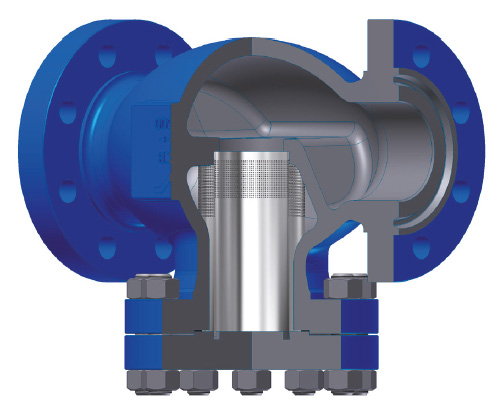

Design

- Forged or casted body and cover

- Bolted cover (BC)

- Net is safely build in between body and cover

Applications

- Power plant, Chemical, Petrochemical, Refining

Media

Depending on the valve materials: water, steam, gas, oil and oil derivates and other non aggressive media

Pressure and temperature

- Class 150 ÷ Class 900

- Temperature up to 600 oC

Materials

- Carbon, heat resistant alloy and stainless steels

Advantages

- Possibility of installation in any position

- Long service life

- Respect to emission standards

- Easy handling and maintenance

Options

- Threaded plug or valve installed on cover for quick draining

- Flanges and welding ends according to : GOST, DIN, EN, etc.

- Other paint finishes are available upon customer’s reques

- Strainer complete with counter flanges, bolting and gaskets

Testing

- Every produced strainer was tested according to API 598